Case Study: Large Jet Patient Loader

Client: Macarthur Jet

Plane Support Solutions

- Design & Drafting

- Engineering

- 3D CAD Images

- CNC Machining

- Advanced Manufacturing

- Assembly

PROJECT DETAILS:

Macarthur Jet are an aircraft charter company that provides medical patient transfer and evacuation services using large jets.

Macarthur Jet are an aircraft charter company that provides medical patient transfer and evacuation services using large jets.

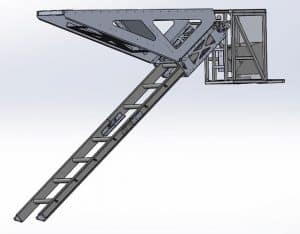

Macarthur Jet purchased a patient loader to support their medical services in order to lift patients up into their aircraft. The loading system purchased form overseas was meant to be easily carried and stowed in the aircraft whilst providing a simple and easily assembled system to load stretcher patients in and out of the aircraft.

Once the loader arrived in Australia, Macarthur Jet discovered the loader was unreliable, heavy and difficult to use.

Plane Support known for providing design and engineering solutions to the aviation industry specialising in aeromedical equipment, was asked to work with Macarthur Jet to upgrade and modernise the patient loader system.

CHALLENGE

Macarthur Jet found the patient loader was heavy, unreliable and difficult to use. The system should be easy to assemble and install by Pilots at all airports in all conditions. Plane Support was contracted to improve the existing loader ensuring that the interface to the stretcher base in the aircraft was maintained. The solution required a redesign to use as many of the existing parts as possible whilst reducing weight and improving the reliability of the loader system. The time frame for this was urgent.

SOLUTIONS

Plane Support used 3D CAD engineering to simulate the system to allow a progressive design and development programme. From the CAD models, the individual modules of the loader system could be accurately developed, manufactured and installed in a short time frame. Plane Supports’ manufacturing used CAD-CAM machining and assembly to reduce the time frames and improve accuracy.

Plane Support used 3D CAD engineering to simulate the system to allow a progressive design and development programme. From the CAD models, the individual modules of the loader system could be accurately developed, manufactured and installed in a short time frame. Plane Supports’ manufacturing used CAD-CAM machining and assembly to reduce the time frames and improve accuracy.

The three main parts redesigned and manufactured included the dolly, the patient loader platform and the rails. These parts all interfaced with the existing power lifter. The rails were converted from heavy aluminium rails to lightweight carbon fibre.

Plane Supported modernised the overall design to a more reliable system that delivered a sturdy, lightweight (32kg fully assembled) patient loader that can safely transfer patients up to 250kg. The project provided a weight saving of approximately 50%.

Plane support are currently re-engineering and upgrading the powered lifter part of the system to further improve the reliability and operation.

RESULTS

Macarthur Jet now has a patient lifter loader that looks modern, is lightweight, stronger, more reliable and easily assembled. When not in use, it stows away easily in the cargo hold, ready to be assembled for its next use.

If you need any assistance with design and engineering solutions Plane Support can be contacted via their website: www.planesupport.com or by phone: 1300 170 884